Understanding Electric Motors and Their Applications

Overview of Electric Motors – Definition, basic working principles, and types of electric motors

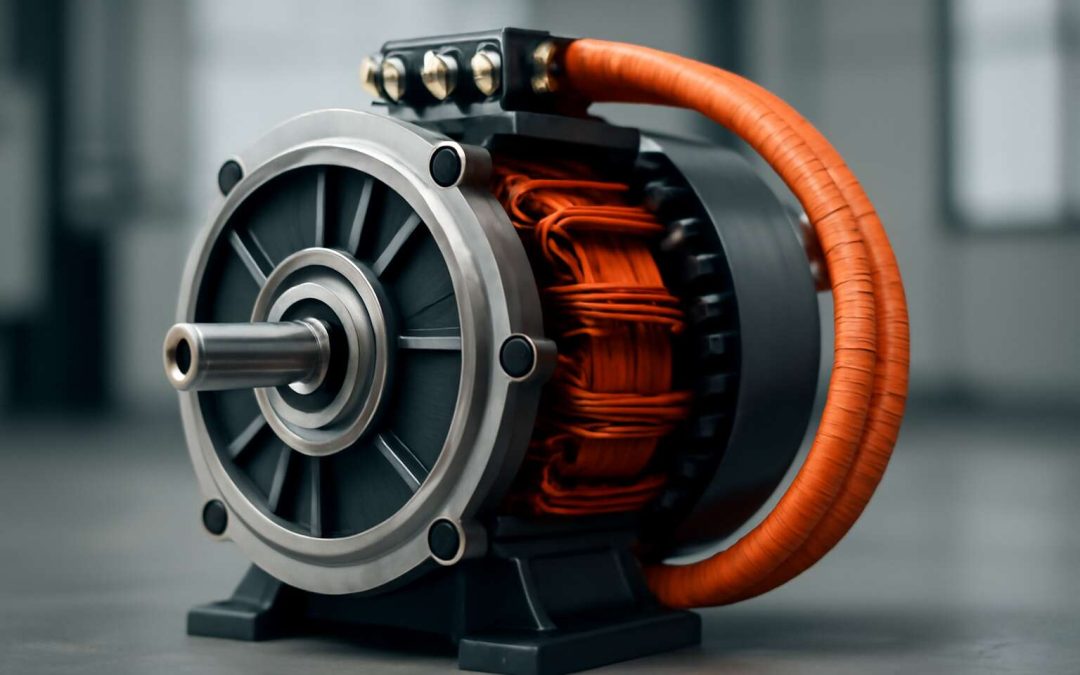

In the shadowy realm of modern machinery, electric motors stand as silent sentinels—powerful yet unseen, driving the heartbeat of countless innovations. These intricate devices convert electrical energy into mechanical motion, a dance of electrons and magnetic fields that whispers through the veins of industry. Their basic working principles hinge on electromagnetic induction, where a current passing through a coil generates a magnetic field, spinning a rotor into life.

Understanding electric motors is essential for grasping their diverse applications. From the sleek turbines powering ships to the compact motors in household appliances, each type serves a unique purpose. In Dartmouth, the focus on electric motors has surged, blending traditional craftsmanship with cutting-edge technology. Whether it’s a brushed motor or a more sophisticated brushless design, each model encapsulates a different facet of this mysterious art form.

- AC motors, ideal for continuous, heavy-duty operations

- DC motors, prized for precise control and variable speed

- Specialized induction motors, used in industrial settings for their durability

In the vast landscape of electric motors dartmouth, the choice of type often mirrors the very essence of the task—an elegant symphony of engineering and utility. As the darkness of the unknown is pierced by the glow of innovation, electric motors continue their silent march, fueling progress in ways both subtle and profound.

Common Industries Using Electric Motors – Manufacturing, automotive, HVAC, and renewable energy sectors

Electric motors have become the unseen architects of progress across numerous industries, especially in Dartmouth, where innovation and tradition intertwine seamlessly. Their versatile nature makes them indispensable in sectors like manufacturing, automotive, HVAC, and renewable energy, fueling the engine of modern development with silent precision. In manufacturing, electric motors dartmouth drive conveyor belts, robotic arms, and assembly lines, transforming raw materials into finished products with remarkable efficiency.

The automotive industry relies heavily on electric motors for electric vehicles, offering a cleaner, more sustainable alternative to traditional engines. Meanwhile, in HVAC systems, these motors regulate climate control, ensuring comfort even in the harshest of winters or summers. The renewable energy sector also harnesses electric motors dartmouth, powering wind turbines and solar tracking systems to maximize energy capture and reduce environmental impact.

- Manufacturing: Automation and machinery driven by electric motors dartmouth

- Automotive: Electric vehicles and component manufacturing

- HVAC: Climate control systems ensuring efficiency and comfort

- Renewable Energy: Wind turbines and solar tracking systems

Benefits of Using Electric Motors – Energy efficiency, cost savings, and environmental impact

Electric motors are the heartbeat of countless modern systems, quietly powering the engines of progress in Dartmouth and beyond. Their ability to convert electrical energy into mechanical motion makes them indispensable across various sectors. Understanding how electric motors dartmouth operate reveals their remarkable versatility, from small appliances to large industrial machinery.

The benefits of using electric motors extend far beyond simple functionality. They offer exceptional energy efficiency, helping industries reduce their carbon footprint while saving on operational costs. In fact, electric motors dartmouth are designed to operate with minimal energy wastage, making them a sustainable choice for forward-thinking businesses. This efficiency translates into significant cost savings over time, especially in high-demand environments like manufacturing or renewable energy projects.

Moreover, electric motors dartmouth contribute positively to the environment by lowering greenhouse gas emissions. Their reliable performance and low maintenance needs mean fewer repairs and less waste. Whether powering wind turbines or HVAC systems, these motors are a cornerstone of eco-friendly innovation. Their adaptability and efficiency ensure that Dartmouth remains at the forefront of sustainable development in various industries.

Why Choose Electric Motors in Dartmouth

Local Industry Needs – Manufacturing plants, industrial facilities, and startups in Dartmouth

In the bustling heart of Dartmouth’s thriving industrial landscape, electric motors are the silent engines powering progress. These marvels of innovation are not just components; they are the pulse of manufacturing plants, transforming raw materials into refined products with graceful efficiency. When industry leaders seek reliability and performance, electric motors dartmouth stand out as the cornerstone of operational excellence.

Local industries recognize that choosing the right electric motors can elevate productivity and sustainability. Dartmouth’s manufacturing facilities, for instance, benefit immensely from motors that combine durability with energy efficiency. Here, every rotation, every motion, is a testament to precision engineering designed to meet the unique needs of the community’s industrial heartbeat.

For startups and established industrial facilities alike, the decision to invest in electric motors dartmouth is a strategic step toward optimized workflows. With advancements in motor technology, companies enjoy benefits such as reduced maintenance costs and enhanced environmental friendliness. It’s no surprise that Dartmouth’s industry leaders are turning to electric motors to propel their visions into reality!

Availability of Electric Motor Services – Sales, repairs, and maintenance providers in Dartmouth

In the vibrant industrial corridors of Dartmouth, where innovation meets tradition, the availability of electric motor services is nothing short of crucial. Whether you’re a burgeoning startup or a seasoned manufacturing titan, access to reliable sales, repairs, and maintenance providers can make all the difference. The local market boasts a wealth of experts skilled in electric motors Dartmouth—ensuring your operations never miss a beat.

What truly sets Dartmouth apart is the seamless integration of these services into the community’s industrial fabric. From quick-turnaround repairs to comprehensive maintenance plans, local providers understand the nuances of electric motors Dartmouth, offering tailored solutions that maximize uptime and efficiency. It’s no exaggeration to say that choosing the right partner can elevate productivity and safeguard your investment.

- Expert sales teams ready to guide you through the latest in electric motor technology

- On-site repairs from technicians familiar with Dartmouth’s unique industrial demands

- Ongoing maintenance to ensure longevity and peak performance of your electric motors Dartmouth

With such a robust support network, businesses in Dartmouth are empowered to push forward with confidence. The availability of comprehensive electric motor services underscores the town’s commitment to industrial excellence—making it an ideal location for those seeking dependable, innovative solutions for their electric motor needs.

Supporting Local Economy – Impact of local businesses providing electric motor solutions

Supporting the local economy in Dartmouth isn’t just a feel-good gesture; it’s a strategic move that fuels growth and resilience. When businesses choose to source their electric motors Dartmouth from local providers, they invest directly back into the community’s thriving industrial landscape. These local specialists are more than vendors—they are partners who understand the unique demands of Dartmouth’s factories and startups.

By prioritizing local electric motor solutions, Dartmouth’s industrial ecosystem becomes more robust. It creates a ripple effect—jobs are sustained, new opportunities arise, and the town’s reputation as an industrial hub strengthens. Electric motors Dartmouth are not just components; they are the heartbeat of innovation, powered by local expertise and commitment.

- Enhanced job creation within Dartmouth’s manufacturing and repair sectors

- Fostering a cycle of continual local innovation and craftsmanship

- Reducing supply chain delays that can hamper operational efficiency

Choosing local electric motor providers in Dartmouth ensures that every watt of energy invested contributes to building a more prosperous, self-sustaining industrial community. Every sale, repair, or maintenance service becomes a step toward reinforcing the town’s industrial backbone—making Dartmouth a beacon of industrial excellence and sustainability.

Types of Electric Motors Available in Dartmouth

AC Motors – Synchronous and Asynchronous motors suitable for various applications

In the realm of electric motors dartmouth, the diversity of options mirrors the complex demands of modern industry. Synchronous and asynchronous motors, each with their unique attributes, serve as the backbone for a multitude of applications, from precision manufacturing to heavy industrial processes. Synchronous motors, celebrated for their ability to maintain constant speed regardless of load variations, are indispensable in scenarios where timing and synchronization are paramount. Conversely, asynchronous motors—more commonly known as induction motors—offer robustness and simplicity, making them ideal for everyday applications that demand durability and cost-effectiveness.

Understanding the distinct characteristics of these motor types is crucial for selecting the right solution. For example, in manufacturing plants in Dartmouth, asynchronous motors are often preferred due to their resilience and straightforward maintenance. Meanwhile, synchronous motors find favor in specialized roles that require exact speed control and high efficiency. The availability of electric motors dartmouth from local suppliers ensures that industries can tailor their choices, optimizing performance while supporting the local economy.

DC Motors – Brushed and brushless options for precise control

In the shadowed corridors of Dartmouth’s industrial landscape, where machinery hums with a ghostly persistence, the choice of electric motors becomes an art of precision and power. Among the myriad options, brushed and brushless motors stand out as the silent sentinels of control, each whispering its own tale of efficiency and innovation. Electric motors Dartmouth offers a spectrum of solutions that cater to both the mundane and the extraordinary, where mastery over motion can mean the difference between stagnation and progress.

Brushed motors, with their simple architecture and reliable performance, have long been the workhorses of many industries. Their design allows for straightforward control, making them ideal for applications requiring moderate precision. However, the true marvel lies in their brushless counterparts—technologically advanced, whisper-quiet, and built for longevity. Brushless motors provide a level of control that borders on the mystical, perfect for projects demanding meticulous accuracy and minimal maintenance.

For those seeking tailored solutions, electric motors Dartmouth supplies a variety of options, including:

- High-performance brushless motors for robotics and automation.

- Compact brushed motors for portable devices and small machinery.

- Specialized motors engineered for extreme conditions or precision tasks.

In the realm of industry, where every rotation counts, choosing the right type of electric motor can elevate a facility from mere operation to an art form—an alchemy of energy, control, and resilience. The local availability of these motors in Dartmouth ensures that industries can harness this power without delay, fueling the engines of progress with a quiet yet relentless force.

Specialty Motors – High torque, inverter-duty, and explosion-proof motors

In Dartmouth’s bustling industrial corridors, the right choice of electric motors can transform the way businesses operate—adding precision, power, and resilience to every project. Electric motors Dartmouth offers a diverse range of solutions tailored to meet the demands of local industries, from high-torque applications to specialized environments. The variety ensures that every operational challenge finds a fitting answer, whether in manufacturing, automation, or energy sectors.

Among the standout options are high-torque electric motors designed to handle heavy loads with ease, ensuring smooth and reliable performance in demanding situations. Inverter-duty motors, known for their adaptability and energy efficiency, optimize processes by providing variable speed control, making them perfect for dynamic applications. For environments where safety is paramount, explosion-proof electric motors are indispensable, built to withstand hazardous conditions without compromising performance.

Understanding these options can be pivotal for local businesses seeking to boost productivity and safety. Whether it’s electric motors Dartmouth powering a new automation line or supporting maintenance of existing infrastructure, the array of specialized motors available ensures that every need is met with precision and expertise.

Choosing the Right Electric Motor for Your Needs

Factors to Consider – Power requirements, efficiency, size, and environment

Choosing the right electric motor for your needs in Dartmouth involves a careful assessment of several critical factors. Power requirements top the list; understanding the load demands of your application ensures you select a motor with sufficient torque and horsepower. Efficiency is equally vital—not only does it reduce operational costs, but it also aligns with sustainable practices increasingly favored across industries.

Size and environmental conditions further influence your decision. An electric motor must fit seamlessly within existing infrastructure while enduring specific conditions such as moisture, dust, or extreme temperatures. For instance, outdoor applications may necessitate explosion-proof or inverter-duty motors to guarantee safety and reliability.

Incorporating these considerations helps you pinpoint the ideal motor—be it an AC motor, DC motor, or specialty variant—that balances performance with longevity. The local availability of electric motors Dartmouth suppliers ensures swift access to tailored solutions, supporting your project’s success while bolstering the community’s industrial resilience.

Custom Solutions – Working with local specialists for tailored motor solutions

Choosing the right electric motor for your project in Dartmouth starts with a nuanced understanding of your unique operational needs. Collaborating with local specialists ensures that your motor solution is not only tailored but also optimized for the specific demands of Dartmouth’s industrial landscape. Working with experts who understand the nuances of electric motors Dartmouth offers guarantees that you get a product that balances performance, durability, and cost-effectiveness.

For those seeking a truly custom fit, consider the following approach:

- Assess the precise power requirements of your application. This ensures your motor delivers the necessary torque and horsepower without unnecessary excess.

- Evaluate the environmental conditions—whether your setup is exposed to dust, moisture, or temperature extremes. Specialty motors such as explosion-proof or inverter-duty variants often excel in these settings.

- Choose the motor type—AC, DC, or specialty—that aligns with your operational goals, whether for high torque, precise control, or energy efficiency.

Partnering with local electric motor providers in Dartmouth not only accelerates access to the right solutions but also supports the community’s industrial resilience. When you work with local specialists, you gain a partner committed to delivering tailored motor solutions that stand the test of time and industry demands.

Cost and Funding Options – Pricing, grants, and incentives available in Dartmouth

Choosing the right electric motor for your needs in Dartmouth involves more than just matching specifications; it’s about finding a solution that aligns with your budget and long-term goals. Cost considerations are crucial, especially for small businesses and startups that operate within tight financial margins. Fortunately, Dartmouth offers a variety of funding options, including grants and local incentives, designed to support the adoption of energy-efficient electric motors.

Many local providers facilitate access to these financial incentives, making it easier for industries to upgrade their machinery without breaking the bank. For example, government-backed grants or renewable energy incentives can significantly offset initial costs, ensuring your investment delivers value over time. In some cases, choosing the right electric motors Dartmouth can also qualify your business for additional rebates, further reducing expenses.

- Assess your operational power needs to avoid overspending on unnecessary capacity.

- Explore available grants and incentives in Dartmouth to maximize affordability.

- Consider long-term savings through energy-efficient motor options that lower operational costs.

Partnering with local electric motor specialists in Dartmouth ensures you’re not only making an informed choice but also supporting the community’s industrial resilience. Whether you’re upgrading existing systems or installing new machinery, understanding your funding options helps you secure the best possible deal while contributing to sustainable growth in the region.

Electric Motor Maintenance and Repair Services in Dartmouth

Importance of Regular Maintenance – Extending motor lifespan and improving performance

In the world of industrial efficiency, neglecting electric motor maintenance can be a costly oversight. Regular upkeep of electric motors Dartmouth isn’t just about preventing breakdowns; it’s a strategic move to prolong the lifespan of these vital components. Proper maintenance enhances performance, reduces unexpected downtime, and ensures that your operations remain smooth and cost-effective.

Skimping on routine checks can lead to decreased efficiency and even catastrophic failures. That’s why many local businesses in Dartmouth prioritize scheduled inspections and repairs. These services typically include cleaning, lubrication, and parts replacement—each a crucial step in maintaining optimal motor function.

For those seeking comprehensive solutions, working with local specialists can unlock tailored maintenance plans. They often offer a range of services such as:

- Motor testing and diagnostics

- Part replacements and rewinding

- Vibration analysis and performance optimization

Investing in regular electric motor maintenance and repairs in Dartmouth isn’t just about keeping things running; it’s about gaining peace of mind knowing your machinery is operating at peak efficiency. Ensuring your electric motors remain in top shape directly correlates with operational success and sustainability in today’s competitive landscape.

Local Repair Shops – Trusted electrical motor repair services in Dartmouth

In the relentless rhythm of industry, a single overlooked fault in your electric motors Dartmouth can ripple into catastrophic failure or crippling downtime. The truth is, these silent powerhouses demand more than just occasional attention—they require expert care rooted in precision and understanding. When local businesses invest in electric motor maintenance and repair services in Dartmouth, they are not merely avoiding failure—they are choosing resilience and longevity.

Trusted repair shops in Dartmouth offer a comprehensive suite of services designed to keep your electric motors operating at peak performance. From meticulous diagnostics to expert rewinding, these specialists understand the nuanced needs of various motor types—be it AC motors, DC motors, or specialty variants. For instance, vibration analysis can uncover hidden stress points before they escalate into costly issues, while timely part replacements ensure your machinery remains efficient and reliable.

Engaging with local experts means tapping into a network that understands Dartmouth’s unique industrial landscape. Whether your operation involves manufacturing, automotive, or renewable energy sectors, these repair shops tailor solutions that align with your specific power requirements, environmental conditions, and operational goals. It’s an investment in not just machinery, but in the very heartbeat of your enterprise—sustaining growth and minimizing risk.

Troubleshooting Common Issues – Overheating, noise, and reduced efficiency

In the symphony of industrial vitality, few instruments are as vital yet as silent as the electric motor. These unassuming marvels, when faltering, threaten to turn the rhythm of operations into a dissonant chaos. Troubleshooting common issues such as overheating, unwelcome noise, or diminished efficiency requires a keen eye and expert touch—traits that local repair shops in Dartmouth possess in abundance.

Overheating is often an unwelcome visitor, signaling underlying problems like insulation breakdown or excessive load. Noise, whether a rhythmic whine or a grinding clatter, can reveal misalignments or bearing failures lurking beneath the surface. Reduced efficiency, the silent thief of productivity, may stem from worn brushes, faulty windings, or contamination. Recognizing these symptoms early can make all the difference in avoiding costly downtime.

For those facing these challenges, trusted electric motor repair services in Dartmouth employ diagnostic techniques such as vibration analysis or thermal imaging to uncover the root cause. They understand that every motor—be it AC, DC, or specialty—has its unique vulnerabilities. Engaging with local experts ensures your electric motors Dartmouth are restored to their optimal performance, safeguarding your enterprise’s heartbeat with precision and care.

Buying Electric Motors in Dartmouth: Tips and Recommendations

Where to Shop – Authorized dealers and trusted suppliers in Dartmouth

Choosing the right electric motors in Dartmouth can significantly influence your project’s efficiency and longevity. With numerous options available, knowing where to shop is crucial for making an informed investment. Authorized dealers and trusted suppliers in Dartmouth offer peace of mind, ensuring you receive quality products backed by reliable service. These local providers often stock a wide range of electric motors dartmouth, from AC motors to specialty variants like explosion-proof or inverter-duty models.

For those seeking tailored solutions, working with local specialists can be a game-changer. They understand the unique needs of Dartmouth’s industrial landscape, whether it’s manufacturing plants or startups. Here’s a quick guide to where you might consider shopping for electric motors dartmouth:

- Authorized dealers with a proven track record in electrical motor sales.

- Trusted suppliers who provide repair and maintenance services, ensuring your investment remains functional.

- Specialist shops offering custom electric motor solutions tailored to specific environmental or operational requirements.

Opting for local sources not only guarantees authenticity but also supports Dartmouth’s economy. Plus, many suppliers offer flexible funding options, making it easier to access essential electric motors dartmouth without breaking the bank.

How to Choose a Reputable Supplier – Customer reviews, service offerings, and product warranties

Choosing the right supplier for electric motors Dartmouth isn’t just about price; it’s about forging a partnership that guarantees reliability, quality, and ongoing support. A reputable provider should offer more than just a vast inventory of electric motors Dartmouth—look for those with stellar customer reviews, comprehensive service offerings, and robust product warranties. These elements are often the silent guardians of your investment, ensuring your project runs smoothly and efficiently.

When vetting potential suppliers, pay close attention to their reputation within the local industry. An established dealer with positive feedback from Dartmouth’s manufacturing plants or startups can signal trustworthy service. Additionally, inquire about their repair and maintenance services, as these are crucial for extending the lifespan of your electric motors Dartmouth and maintaining peak performance.

- Check customer reviews for honesty and consistency in service delivery.

- Verify the warranty coverage to protect against unforeseen issues.

- Ensure the supplier offers tailored solutions if your project demands specialty motors like explosion-proof or inverter-duty models.

Ultimately, a reputable supplier will not only deliver quality electric motors Dartmouth but also provide expert guidance, helping you navigate the complex landscape of motor specifications and environmental considerations. Choosing wisely ensures your investment remains resilient in Dartmouth’s dynamic industrial environment.

Integrating Electric Motors with Existing Systems – Compatibility and installation considerations

When considering the purchase of electric motors Dartmouth, one must venture beyond mere specifications and delve into the realm of seamless integration. Compatibility with existing systems is paramount, ensuring that these powerful devices harmonize with your current machinery without disrupting the flow of operations. An electric motor that fits like a missing piece in a grand puzzle can transform an ordinary setup into a symphony of efficiency.

Installation considerations should not be overlooked. A carefully planned installation minimizes downtime and prevents costly errors. For instance, verifying the motor’s size and power requirements against your facility’s infrastructure can save you from future headaches. When selecting electric motors Dartmouth, it’s wise to consult with local specialists who can provide insights into environmental factors—such as temperature fluctuations or exposure to moisture—that influence motor performance.

Furthermore, integrating electric motors with existing control systems, like variable frequency drives or automation platforms, demands attention to detail. Some projects may benefit from inverter-duty models, which offer superior adaptability. To streamline your decision-making process, consider this:

- Assess your current system’s power specifications.

- Ensure the motor’s environmental resilience matches your operational conditions.

- Collaborate with local experts to customize a solution that aligns perfectly with your needs.

Such meticulous planning ensures that your investment in electric motors Dartmouth not only propels your operations forward but also sustains peak performance over time. The magic of a well-integrated motor lies in its ability to become an invisible yet indispensable part of your industrial narrative, enhancing both productivity and longevity.

Future Trends in Electric Motors and Sustainability in Dartmouth

Advancements in Motor Technology – Smart motors, energy-efficient designs, and automation

The horizon of electric motors in Dartmouth is shimmering with possibilities, driven by relentless innovation and a collective pursuit of sustainability. As the world pivots toward greener energy paradigms, Dartmouth’s advancements in motor technology exemplify this global shift, blending smart automation with energy-efficient designs. These emerging trends are not merely incremental; they herald a transformative era where electric motors become smarter, more adaptive, and environmentally harmonious.

Future trends in electric motors dartmouth are characterized by the integration of intelligent systems that anticipate operational needs, reducing waste and optimizing performance. Smart motors equipped with sensors and IoT connectivity enable real-time monitoring, predictive maintenance, and seamless integration into automated systems. Simultaneously, energy-efficient designs—such as high-performance inverter-driven motors—are reducing power consumption and carbon footprints. The focus on sustainability is further bolstered by innovations that promote the use of recyclable materials and eco-friendly manufacturing processes, aligning local industry goals with global environmental standards.

In this landscape, the push toward automation is especially noteworthy. Electric motors dartmouth are increasingly embedded within advanced manufacturing frameworks, supporting Industry 4.0 initiatives. This convergence of smart technology and sustainability not only preserves resource integrity but also elevates operational efficacy. As Dartmouth continues to lead in these developments, the synergy of innovative motor technology and ecological consciousness promises a resilient, cleaner future for industrial and commercial sectors alike.

Green Initiatives – Supporting sustainable energy solutions with electric motors

Electric motors in Dartmouth are at the forefront of a sustainable revolution. As industries shift towards greener energy solutions, innovative trends are shaping the future of electric motors in Dartmouth. These advancements are not only about efficiency but also about embedding eco-conscious practices into everyday operations. The integration of smart systems and automation is making these motors more adaptive and resource-efficient than ever before.

Future trends in electric motors dartmouth include the development of intelligent systems that can predict operational needs. This means real-time data monitoring, predictive maintenance, and seamless automation. Such features help reduce waste and maximize performance. Additionally, energy-efficient designs—like inverter-driven motors—are significantly lowering power consumption and carbon emissions. Supporting these innovations are eco-friendly manufacturing processes and recyclable materials, which align local industry goals with global sustainability standards.

Supporting sustainability, Dartmouth’s electric motors contribute directly to green initiatives. They enable renewable energy projects, improve energy management, and bolster the local economy through sustainable manufacturing. As this sector continues to evolve, the push towards environmentally harmonious solutions remains a priority. Electric motors in Dartmouth are not just machines; they are catalysts for a cleaner, more efficient future.

Local Outlook – Dartmouth’s role in innovation and adoption of advanced electric motor technologies

In Dartmouth, the horizon of electric motor technology is shimmering with innovation. As sustainability becomes a guiding star, local industries are pioneering advancements that blend efficiency with ecological harmony. The future of electric motors in Dartmouth is not just about powering machines; it’s about transforming the very fabric of industrial progress—more intelligent, more adaptable, and significantly greener.

Emerging trends include the rise of smart electric motors in Dartmouth that leverage real-time data monitoring to optimize operations seamlessly. These advancements enable predictive maintenance, reducing downtime and energy waste. Moreover, energy-efficient designs like inverter-driven motors are revolutionizing power consumption, aligning local manufacturing with global sustainability goals. Dartmouth’s commitment to eco-friendly manufacturing processes—using recyclable materials and green technologies—cements its role in the green energy revolution.

- Integration of automation systems for smarter energy management

- Development of high-torque, inverter-duty, and explosion-proof motors tailored for diverse industrial needs

- Adoption of recyclable components and eco-conscious production standards

Supporting these technological leaps, Dartmouth’s electric motors contribute significantly to renewable energy projects, such as solar and wind installations. The local industry’s proactive embrace of advanced electric motor technologies underscores their pivotal role in fostering a sustainable future. As Dartmouth continues to evolve as an innovation hub, its electric motor sector embodies a commitment to environmental stewardship and technological excellence—proof that progress can be both powerful and planet-friendly.