Understanding Magnet-Free Electric Motors

What Are Magnet-Free Electric Motors?

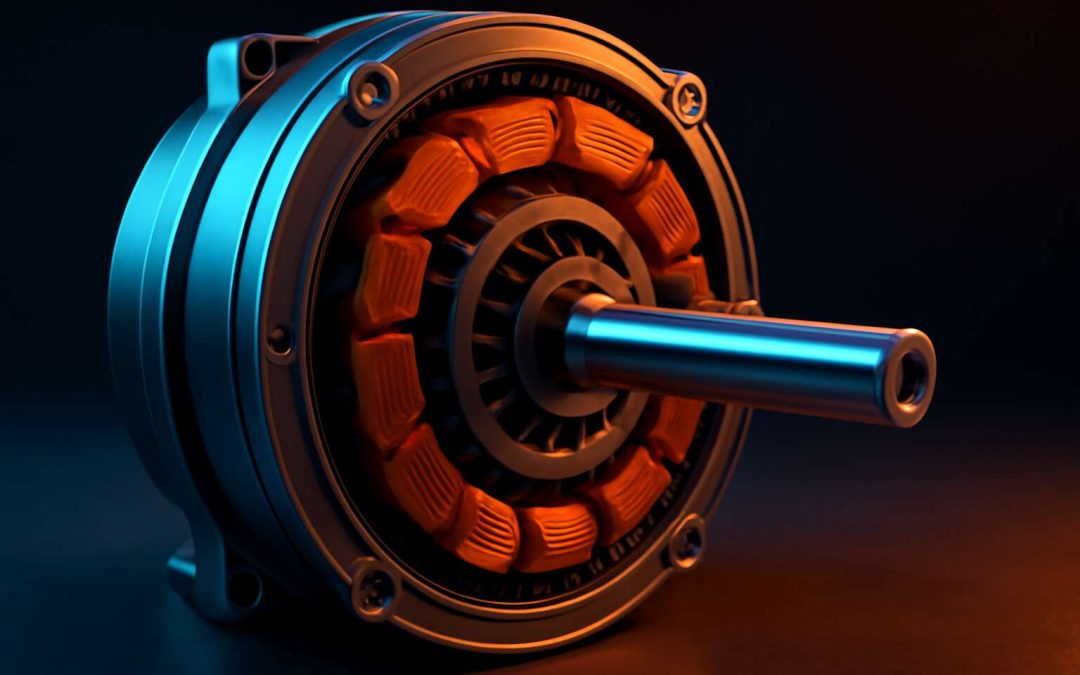

Electric motors without magnets are revolutionising the way we think about sustainable and efficient engineering. Unlike traditional motors that rely heavily on permanent magnets, these innovative designs harness alternative methods to generate the magnetic fields necessary for operation. This shift not only reduces reliance on rare-earth materials but also opens new avenues for environmentally friendly technology. The concept is intriguing because it challenges long-held assumptions about what makes an electric motor effective, prompting engineers and researchers to explore new magnetic topologies.

Understanding magnet-free electric motors involves appreciating their core principle: they utilise electromagnetic induction and carefully engineered coil arrangements to produce motion without the need for permanent magnets. This approach can lead to lighter, more cost-effective, and more environmentally sustainable motors. Whether for electric vehicles, industrial machinery, or renewable energy systems, electric motors without magnets are proving to be a compelling evolution in motor design.

Some key features include:

- Reduced dependency on rare-earth materials, making them more sustainable and less geopolitically sensitive.

- Potential for simplified manufacturing processes, lowering production costs.

- Enhanced thermal management due to the absence of permanent magnets, which often require complex cooling solutions.

Differences Between Magnet-Free and Traditional Electric Motors

Electric motors without magnets represent a profound departure from classical electromagnetic paradigms, subtly reshaping our understanding of motor functionality. Unlike traditional electric motors that depend on permanent magnets to generate the magnetic flux, magnet-free counterparts rely solely on electromagnetic induction and innovative coil arrangements. This fundamental difference not only alters the internal architecture but also influences performance characteristics, durability, and environmental impact.

In essence, the divergence between magnet-free electric motors and their traditional counterparts lies in their magnetic field generation. While conventional motors harness the fixed magnetic fields of permanent magnets, magnet-free designs dynamically produce magnetic fields through carefully orchestrated electrical currents. This distinction fosters a series of advantages, including reduced reliance on rare-earth materials and simplified manufacturing processes.

Moreover, the absence of permanent magnets often results in less heat generation and improved thermal management—crucial factors for high-performance applications. The following list highlights some core differences:

- Magnetic field source: permanent magnets versus electromagnetic induction.

- Material dependency: reliance on rare-earth elements versus standard copper wiring.

- Thermal characteristics: heat dissipation efficiency due to absence of magnets.

Thus, understanding these fundamental differences opens a new realm of possibilities for designing sustainable and cost-effective electric motors without magnets, challenging long-standing engineering conventions with innovative solutions that resonate beyond mere efficiency.

Why Consider Magnet-Free Alternatives?

Electric motors without magnets are quietly transforming the industry, offering a compelling alternative to traditional designs. As industries seek more sustainable and cost-efficient solutions, these magnet-free motors stand out not just for their innovative approach but for their potential to redefine how we think about energy use and environmental impact.

Why consider magnet-free alternatives? For one, they eliminate the reliance on rare-earth elements, which are often associated with supply chain vulnerabilities and ecological concerns. This shift not only reduces material dependency but also paves the way for simplified manufacturing processes, making production more accessible and affordable.

- Lower environmental footprint due to reduced mining and processing of scarce materials.

- Enhanced thermal management, leading to less heat generation and longer lifespan.

- Potential for increased durability, as fewer components susceptible to wear and tear are involved.

In regions where resource availability is uncertain, electric motors without magnets offer a resilient, forward-thinking solution that aligns with global sustainability goals. Their growing popularity underscores a fundamental realisation: innovation doesn’t always mean more complexity — sometimes, it’s about stripping things back to their core to find new possibilities.

Types of Electric Motors Without Magnets

Switching Reluctance Motors

In the realm of electric innovation, switching reluctance motors stand as a testament to the marvels achievable without the reliance on magnets. These enchanted devices harness the magnetic reluctance—a force as old as the universe itself—to generate motion with a simplicity that belies their power. Unlike traditional designs, electric motors without magnets embrace a design philosophy rooted in magnetic pathways, creating a dance of flux that propels the rotor with remarkable efficiency.

Within this category, the most celebrated are the synchronous reluctance motors, which elegantly convert electrical energy into kinetic force by aligning magnetic fields through carefully crafted salient poles. Their operation is akin to a mythical symphony of magnetic forces, orchestrating movement without the need for rare earth elements. For those seeking a harmonious balance of sustainability and performance, these motors deliver a compelling saga of innovation.

Induction Motors

When it comes to electric motors without magnets, induction motors are undoubtedly the rock stars of the show. These workhorses rely on electromagnetic induction to produce motion, sidestepping the need for rare earth magnets entirely. Their simple yet robust design makes them a favourite in industrial settings where durability and reliability are paramount.

Induction motors operate on the principle of creating a rotating magnetic field in the stator, which then induces a current in the rotor. This process results in torque without any permanent magnets involved, making them a sustainable choice for eco-conscious engineers. Here are some key features of induction motors:

- High efficiency in various load conditions

- Minimal maintenance due to their rugged construction

- Cost-effective, especially in large-scale applications

From small appliances to massive industrial machinery, electric motors without magnets like induction motors prove that simplicity often leads to the most powerful results. Their ability to deliver reliable performance while avoiding the pitfalls of rare earth dependency cements their status as champions of magnet-free motor technology.

Linear Motors

Among the captivating realm of electric motors without magnets, linear motors stand out as a marvel of precision and innovation. These motors transform electrical energy directly into linear motion, bypassing the rotational process altogether. Imagine the elegance of a movement that is fluid, direct, and without the clutter of gears or pulleys—this is the promise of linear motors.

Designed with simplicity and efficiency in mind, linear motors are often employed in high-speed applications such as transportation systems and advanced manufacturing. Their ability to deliver rapid, smooth motion without the need for permanent magnets makes them a compelling choice for eco-conscious engineers. Here are some key features of linear motors:

- High acceleration and deceleration capabilities

- Minimal maintenance requirements due to fewer moving parts

- Enhanced precision and control for delicate operations

Whether in cutting-edge robotics or sophisticated conveyor systems, electric motors without magnets like linear motors exemplify how innovation can harness the power of electromagnetism in the most direct, elegant manner. Their magnet-free design not only champions sustainability but also underscores the beauty of engineering free from rare earth dependencies—the perfect blend of form and function in modern technology.

Other Emerging Technologies

Beyond the familiar landscape of linear and reluctance motors, a fascinating array of technologies continues to emerge within the realm of electric motors without magnets. These innovations are redefining efficiency and sustainability, proving that the future of motor design is not only about power but also about elegance and ecological responsibility. Among these, *switched reluctance motors* stand out for their robustness and simplicity, using variable magnetic reluctance to generate motion without the need for permanent magnets.

Another compelling avenue is the development of *synchronous reluctance motors*, which leverage magnetic anisotropy to achieve high efficiency. These motors are celebrated for their resilience and low maintenance, especially in demanding industrial environments. Their design minimises the use of rare earth materials, making them an attractive choice for those committed to sustainable engineering.

- Innovative coil winding techniques that enhance electromagnetic interaction without magnets.

- Advanced power electronics that improve control and responsiveness in magnet-free motors.

As these emerging technologies demonstrate, electric motors without magnets are no longer a niche but a dynamic frontier in modern engineering. They embody a pursuit of harmony between technological progress and environmental stewardship, transforming the way we conceive motion itself.

Advantages of Magnetic-Free Electric Motors

Cost-Effectiveness

In a world increasingly captivated by sustainable innovation, the appeal of electric motors without magnets shines brighter than ever. These marvels of engineering offer a cost-effective alternative to traditional magnet-based designs, providing both economic and environmental benefits. Without the reliance on rare-earth materials, which often come with steep prices and supply chain uncertainties, magnet-free electric motors open doors to accessible, scalable solutions that are easier to produce and maintain.

The financial advantages of electric motors without magnets extend beyond raw material savings. Their simpler construction reduces manufacturing complexity and labour costs, translating into lower prices for end-users. Moreover, their durability and reduced need for maintenance make them an attractive choice for industries eager to optimise operational expenses. As the demand for greener, more affordable technology surges, these motors stand as a testament to ingenuity — proving that efficiency and affordability can coexist in harmony.

Material Availability and Sustainability

In an era where resource scarcity and environmental consciousness dictate technological progress, the material availability of electric motors without magnets becomes a pivotal advantage. These motors sidestep the reliance on rare-earth elements, whose supply chains are often as unpredictable as British weather. Instead, they utilise abundant materials, making them not only more sustainable but also more resilient to geopolitical shocks.

Furthermore, the sustainability of electric motors without magnets is rooted in their reduced ecological footprint. The manufacturing process demands fewer extraction efforts and minimises hazardous waste, aligning perfectly with the green ambitions of modern industry. This shift towards more sustainable materials ensures that innovation no longer comes at the expense of the planet, but rather, complements it.

In fact, the appeal of these motors is heightened by their environmental credentials, which resonate with a growing consumer and regulatory demand for greener solutions. With increased material availability, the production of electric motors without magnets can scale more reliably, fostering a future where sustainable technology becomes the norm rather than the exception. This strategic advantage underscores a trend — a move towards more accessible, eco-friendly, and resilient motor solutions that can power our world without draining its resources.

Reduced Magnetic Interference

One of the most understated yet impactful benefits of electric motors without magnets is their reduced magnetic interference. Unlike traditional motors relying on magnets, these innovative designs minimise stray magnetic fields that can disrupt nearby electronic devices. This attribute is especially crucial in sensitive environments—think hospitals or precision manufacturing—where even the slightest magnetic hiccup can lead to costly errors.

Moreover, the absence of magnets means fewer electromagnetic disturbances, translating into quieter, more stable operation. The lack of magnetic flux leakage contributes to a cleaner electromagnetic environment, which, in turn, enhances the longevity and reliability of surrounding equipment. For industries eager to optimise operational harmony, electric motors without magnets offer a compelling solution that combines efficiency with a touch of social finesse—less noise, less fuss.

- Enhanced compatibility with sensitive electronics

- Reduced electromagnetic noise, leading to quieter operation

- Lower risk of interference with communication systems

Such advantages position electric motors without magnets as an increasingly attractive option—one that marries technological sophistication with environmental mindfulness, all while maintaining impeccable social decorum in the modern workplace.

Potential for High Efficiency

Electric motors without magnets are swiftly gaining recognition for their potential to achieve high efficiency levels. Without the reliance on rare earth magnets, these motors can utilise innovative designs like reluctance or induction mechanisms to optimise energy conversion. This not only reduces costs but also maximises performance, especially in applications demanding sustained, reliable operation.

One of the most compelling advantages is their ability to operate with minimal energy loss. The absence of magnetic hysteresis effects means that these motors can maintain a steady, smooth output—often surpassing traditional magnet-based counterparts. This efficiency translates into lower operational costs and a smaller carbon footprint, making them an alluring choice for eco-conscious industries.

- Enhanced thermal management, reducing overheating risks

- Fewer material constraints, allowing for scalable, custom designs

- Superior durability in demanding environments, thanks to simplified construction

In an era where energy efficiency and sustainability are paramount, electric motors without magnets present a fascinating frontier — promising not just technological innovation but a greener, more stable future for industrial automation and beyond. Their potential for high efficiency is undeniable — a true game-changer in the world of electric motor technology.

Challenges and Limitations

Performance Constraints

While electric motors without magnets present a compelling alternative to traditional designs, they are not without their inherent challenges. Performance constraints often stem from the reliance on electromagnetic induction and reluctance principles, which can limit their operational efficiency in certain applications. Unlike magnet-based motors, these systems frequently demand meticulous engineering to optimise magnetic flux paths, a process that can be both complex and costly.

Furthermore, the torque density achievable by electric motors without magnets tends to lag behind that of their magnet-equipped counterparts. This limitation becomes especially pronounced in high-performance scenarios where compactness and power output are paramount. As a result, engineers often grapple with balancing efficiency, size, and cost, navigating a labyrinth of trade-offs that can hinder widespread adoption. Nevertheless, ongoing advances continue to push the boundaries of what these magnet-free solutions can accomplish, even as they confront performance boundaries rooted in fundamental electromagnetic principles.

Complex Control Systems

Electric motors without magnets are revolutionising the industry, yet their complexity often masks the intricate control systems required for optimal performance. Unlike traditional motors, these magnet-free designs depend heavily on precise electromagnetic coordination, which demands sophisticated algorithms and real-time adjustments. This complexity can be daunting, pushing engineers into a labyrinth of tuning and calibration.

Such advanced control systems are not just a technical challenge—they can also inflate costs and extend development timelines. For example, implementing variable reluctance control or adjusting flux paths requires specialised hardware and software, making these solutions less accessible for mass production. Additionally, fluctuations in operating conditions can significantly impact efficiency, forcing continuous monitoring and adjustment.

- Maintaining stability under variable loads

- Balancing efficiency with cost and size constraints

- Ensuring consistent torque output amidst electromagnetic fluctuations

Ultimately, the challenge lies in developing control architectures that are both robust and economical, pushing the boundaries of what electric motors without magnets can achieve in complex, high-demand applications. The ongoing quest to simplify these control systems remains a pivotal hurdle on the path to broader adoption of magnet-free motor technology.

Limited Power Density

Electric motors without magnets face a significant hurdle: limited power density. Unlike traditional motors that leverage magnetic fields for maximum torque, magnet-free designs rely on electromagnetic interactions that often restrict their energy output relative to their size. This can be a critical disadvantage in applications demanding high power in compact spaces.

One core challenge is balancing performance with size constraints. These motors tend to be bulkier because they need larger iron cores or more sophisticated winding arrangements to achieve comparable power levels. For industries where space is at a premium, this limitation can hinder adoption.

Furthermore, the electromagnetic forces generated in electric motors without magnets are inherently weaker. This results in lower torque density, which can compromise overall efficiency and performance. In demanding environments, maintaining consistent power output becomes complex, especially under fluctuating load conditions.

To address these issues, engineers often explore innovative design strategies, such as optimizing flux paths or employing advanced materials. However, these solutions increase complexity and costs, making the pursuit of higher power density in magnet-free motors a persistent challenge.

Manufacturing and Maintenance Issues

Manufacturing and maintaining electric motors without magnets presents a labyrinth of intricate challenges that often escape the casual observer. The complexity of these devices stems from their reliance on precise winding configurations and flux management, demanding high levels of craftsmanship and specialised manufacturing techniques. This sophistication can translate into increased production costs and longer lead times, making scalability a formidable hurdle.

Moreover, the maintenance of electric motors without magnets is fraught with its own set of hurdles. Their design often involves complex electromagnetic interactions that are sensitive to wear and tear, especially in environments subject to vibration or thermal stress. Troubleshooting these motors requires a deep understanding of their nuanced operation, which can escalate downtime and repair expenses.

In some cases, manufacturers face difficulties sourcing specialised materials or components that are vital for optimal performance. The intricacy of winding arrangements and core materials necessitates meticulous quality control, and any deviation can significantly impair efficiency. Overall, the specialised nature of electric motors without magnets makes their production and upkeep a demanding endeavour, often limiting their widespread adoption in demanding industrial applications.

Applications of Magnet-Free Electric Motors

Industrial Machinery

In the realm of industrial machinery, electric motors without magnets are quietly revolutionising how we approach power and efficiency. These innovative motors find their place in environments where magnetic interference could compromise sensitive equipment or where sustainability is a priority. From robotics to large-scale manufacturing, their application is as diverse as the industries they serve.

One remarkable aspect of magnet-free electric motors is their adaptability in demanding settings. They excel in applications where durability and low maintenance are paramount. For example, in conveyor systems or automated assembly lines, these motors deliver reliable performance without the complications posed by magnetic materials. Their design often allows for seamless integration into existing machinery, making them a versatile choice in modern industry.

Furthermore, the utilisation of electric motors without magnets extends into specialised sectors such as renewable energy and transportation. Their ability to operate efficiently in high-temperature environments or under continuous load conditions underscores their potential. As industries seek greener solutions, these motors offer not just sustainability but also a promise of innovation-driven productivity.

Electric Vehicles

Electric motors without magnets are quietly transforming the landscape of electric vehicle (EV) technology, offering a compelling alternative to traditional magnet-based systems. These magnet-free electric motors harness electromagnetic principles like reluctance and induction, providing an innovative pathway for sustainable transportation. With ongoing advancements, they are increasingly capable of delivering high torque and efficiency, crucial for powering modern EVs.

In the realm of electric vehicles, the absence of magnets means fewer rare-earth materials are needed, reducing both costs and environmental impact. This shift not only bolsters sustainability but also enhances resilience against supply chain disruptions. Furthermore, electric motors without magnets excel in high-temperature conditions often encountered in EV powertrains, ensuring consistent performance even during extended driving periods.

- Reduced reliance on scarce materials, making EV manufacturing more sustainable.

- Enhanced thermal stability, allowing for reliable operation under demanding conditions.

- Potential for simplified cooling systems, lowering maintenance complexities.

As the industry accelerates towards greener mobility, electric motors without magnets stand out as a promising technology—fueling a future where performance, sustainability, and innovation harmoniously converge in electric vehicles.

Renewable Energy Systems

As the world pivots towards sustainable energy solutions, electric motors without magnets are quietly carving out a vital niche in renewable energy systems. These innovative motors, often based on reluctance or induction principles, excel in applications where efficiency and environmental consciousness are paramount. Their ability to operate without rare-earth materials not only reduces ecological impact but also aligns perfectly with the green ethos driving modern technology.

In renewable energy setups such as wind turbines and solar power plants, electric motors without magnets demonstrate remarkable resilience and reliability. They are particularly suited for large-scale operations where durability and thermal stability are essential. For example, wind turbines benefit from magnet-free machines that can withstand high temperatures and variable loads without sacrificing performance, thus ensuring a steady energy output.

Furthermore, these motors are increasingly integrated into linear motion systems used in solar tracking devices and other solar energy infrastructure. Their capacity for high efficiency and minimal maintenance makes them an appealing choice for long-term energy generation. As the push for greener alternatives accelerates, electric motors without magnets stand ready to power the next generation of renewable energy technology with elegance and eco-consciousness.

Consumer Electronics

In the realm of consumer electronics, electric motors without magnets are quietly revolutionising device design, blending efficiency with sustainability. These magnet-free motors, often based on reluctance or induction principles, enable manufacturers to create slimmer, more reliable gadgets that perform seamlessly. Their absence of rare-earth materials not only reduces environmental impact but also ensures that devices remain lightweight and less prone to magnetic interference—an essential trait in delicate electronics.

From compact drones to sophisticated home automation systems, electric motors without magnets are increasingly integral to modern innovation. Their ability to deliver high torque at low speeds and operate with minimal maintenance makes them a favourite among designers aiming for longevity and eco-consciousness. As consumer electronics continue to evolve, magnet-free motors epitomise a harmony between technological advancement and sustainable development.

In essence, the adoption of electric motors without magnets in consumer products signifies a shift towards greener, more resilient electronic devices—an elegant dance of engineering that champions both performance and planetary well-being.

Future Trends and Innovations in Magnet-Free Motor Technology

Advances in Materials

The future of electric motors without magnets is poised to redefine efficiency and sustainability in ways we once only dreamed of. Advances in the development of new materials are unlocking potential that could surpass traditional magnet-based systems, especially as the demand for greener, more reliable technology surges. Cutting-edge research focuses on innovative alloys and composites, which promise to enhance magnetic flux in ways previously thought impossible. This evolution is not just about replacing magnets; it’s about creating a new paradigm for motor design—one that is cleaner, more adaptable, and inherently more resilient.

As material science progresses, the horizon is expanding for electric motors without magnets. Researchers are exploring high-performance steel, amorphous alloys, and even nano-engineered composites that could dramatically improve flux density and thermomechanical stability. These innovations are critical because they directly address the performance constraints of current magnet-free designs, such as limited power density and complex control systems. The potential for high efficiency and reduced magnetic interference makes these motors ideal for a broad range of applications, from industrial machinery to electric vehicles. With each breakthrough, the line between science fiction and reality blurs, hinting at a future where magnet-free electric motors become the norm rather than the exception.

Control Algorithms and Automation

As the landscape of electric motors without magnets evolves, innovative control algorithms and automation techniques are at the forefront of this transformation. These advancements are not merely tweaks but represent a seismic shift in how these motors are managed and optimised for real-world performance. Sophisticated sensorless control systems now harness AI-driven algorithms that dynamically adjust parameters in real time, enhancing efficiency and responsiveness.

Future trends indicate a move towards intelligent, self-learning systems that can adapt to changing loads and environmental conditions with minimal human intervention. This level of automation promises to unlock unprecedented levels of precision and reliability in applications spanning industrial machinery to renewable energy systems.

Incorporating machine learning into control strategies enables the prediction of operational anomalies before they impact performance. These innovations are shaping a new paradigm for electric motors without magnets, where seamless integration of control algorithms ensures smoother operation, reduced energy wastage, and enhanced longevity. It’s a thrilling glimpse into a future where the harmony between technology and sustainability reaches new heights.

Hybrid Motor Designs

The future of electric motors without magnets is poised for remarkable innovation. Hybrid motor designs are emerging as a key trend, combining different electromagnetic principles to optimise performance and efficiency. These sophisticated configurations aim to overcome the limitations of traditional magnet-free motors, such as power density and control complexity.

One exciting development involves integrating variable reluctance and induction technologies into hybrid systems. This approach allows for smoother operation and enhanced adaptability across diverse applications—from industrial machinery to renewable energy systems. As these hybrid designs mature, they promise to deliver higher efficiency without sacrificing reliability.

Furthermore, advancements in materials and control algorithms are driving a new wave of self-learning, adaptive systems. These innovations enable electric motors without magnets to respond intelligently to changing operational conditions, reducing energy wastage. The shift towards smarter, more sustainable motor technologies is not just a trend but a necessity in the pursuit of greener, more efficient energy solutions.

Research and Development Outlook

As the quest for sustainable energy solutions accelerates, the future of electric motors without magnets is poised for transformative breakthroughs. Cutting-edge research is revealing new pathways where innovation converges with efficiency, promising to redefine what’s possible in motor technology. The integration of advanced materials and intelligent control algorithms is at the forefront of this evolution, enabling electric motors without magnets to operate with unprecedented precision and adaptability.

One compelling trend involves the development of hybrid motor systems that combine the strengths of variable reluctance and induction technologies. These hybrid configurations are not merely incremental improvements; they represent a paradigm shift, offering smoother operation and broader application scopes. In particular, the potential for these motors to deliver higher performance with reduced reliance on rare-earth materials makes them attractive for industries ranging from electric vehicles to renewable energy systems.

Looking ahead, the R&D landscape is rich with promise. Researchers are exploring novel magnetic materials that could further optimise magnetic flux control, while sophisticated automation and machine learning algorithms are enabling self-adaptive, smarter motor systems. These innovations are set to unlock new levels of efficiency and reliability in electric motors without magnets, ensuring their relevance in a rapidly evolving technological ecosystem.

- Enhanced material properties enabling more efficient flux management

- Integration of AI-driven control systems for real-time optimisation

- Modular hybrid designs combining different electromagnetic principles

- Advanced manufacturing techniques reducing costs and improving durability

With each breakthrough, the horizon of possibilities widens—ushering in a new era where electric motors without magnets become central to sustainable, high-performance energy systems. The journey into this realm of innovation is nothing short of exhilarating, promising a future where efficiency, sustainability, and technological ingenuity intersect seamlessly.

Choosing the Right Magnet-Free Electric Motor

Factors to Consider

Choosing the right electric motors without magnets demands a keen eye for several critical factors that could influence performance and longevity. One essential consideration is the type of technology employed—whether switching reluctance or induction—each offering distinct advantages in efficiency and control complexity. For instance, electric motors without magnets often leverage *variable speed capabilities*, making them ideal for applications requiring precise regulation.

Material availability and sustainability are also pivotal; selecting components that minimise environmental impact not only aligns with eco-conscious trends but also ensures long-term reliability. Additionally, the *performance constraints* of magnet-free designs—such as limited power density—must be balanced against the benefits of reduced magnetic interference.

A detailed understanding of these factors can unlock the full potential of magnet-free solutions, transforming industrial machinery and renewable energy systems alike. As innovation accelerates, the strategic choice of an appropriate motor type becomes more intriguing, revealing a landscape rich with possibilities for efficiency and sustainability.

Performance Metrics

Performance metrics serve as the heartbeat of electric motors without magnets, guiding us through a labyrinth of design choices and operational expectations. To truly gauge their potential, one must examine parameters like torque density, efficiency, and thermal management — each offering a window into how these motors function under real-world stresses. Unlike traditional motors, those without magnets often rely on sophisticated control algorithms to optimise performance, making these metrics even more vital.

When selecting an electric motor without magnets, it’s essential to weigh these key performance indicators. For example, a high torque-to-weight ratio might be less critical if thermal dissipation is poor, leading to premature wear. Conversely, efficiency metrics reveal how well the motor converts electrical energy into mechanical power, a crucial factor in applications like renewable energy systems. In this context, understanding the balance between performance constraints and operational demands becomes a strategic endeavour — one that determines the success or failure of a given project.

In the pursuit of excellence, engineers often turn to

- power density

- thermal stability

- control response times

as critical benchmarks. These elements collectively shape the real-world efficacy of electric motors without magnets, emphasising that beyond raw capability, sustainable and precise operation remains the ultimate goal. Such metrics aren’t just numbers — they are the moral compass guiding innovation and reliability in this burgeoning field.

Cost vs. Efficiency Trade-offs

Choosing the right electric motor without magnets involves balancing cost and efficiency—a decision that can make or break a project. These motors often require sophisticated control systems, which can add to initial expenses. However, their potential for high efficiency and reduced magnetic interference makes them attractive, especially in applications demanding sustainability and innovation.

Cost considerations are crucial; while electric motors without magnets might seem pricier upfront due to complex manufacturing processes, their long-term energy savings often outweigh these initial costs. Efficiency metrics are the key to unlocking this potential. For instance, high efficiency in these motors translates directly into lower energy consumption, which is vital for renewable energy systems and electric vehicles.

The trade-offs are clear: investing in advanced control algorithms and materials may boost efficiency but can also escalate costs. Ultimately, a careful evaluation of performance metrics versus budget constraints will guide the optimal choice, ensuring the selected electric motor without magnets delivers both value and performance.

Compatibility with Existing Systems

Choosing the right electric motors without magnets isn’t merely a technical decision; it’s a philosophical one. Compatibility with existing systems requires a nuanced understanding of how these innovative motors integrate into the broader machinery landscape. For instance, many industrial setups rely heavily on traditional motor architectures, so ensuring seamless adaptation can be a delicate dance of engineering precision.

Before making a commitment, consider the following aspects:

- Assess the electric motors without magnets’ ability to interface with control systems already in place.

- Evaluate the compatibility of power supplies and drive electronics to prevent costly retrofits.

- Examine the physical footprint—dimensions and mounting options—to ensure they fit within existing frameworks.

Not all electric motors without magnets are created equal, and their integration hinges on a clear understanding of these subtle yet profound distinctions. Compatibility isn’t just about technical specs; it’s about aligning the motor’s behaviour with the intended purpose, whether it’s in renewable energy systems or electric vehicles. When these elements align, the potential for a harmonious, efficient system becomes more than just a possibility—it becomes a reality.